Precision in every piece.

Promise in every partnership.

Company Overview

At Standout, we are a trusted provider of steel fabricated components, catering to diverse industries such as RV, Boating, Aerospace, and more. Our commitment rests on the pillars of uncompromising quality, unparalleled customer service, and reliable on-time delivery. With a dedication to innovation, we offer free prototyping and engineering support to ensure your vision becomes reality. Equipped with state-of-the-art tools, including our fiber laser, press break, and robotic weld cells, we bring precision and efficiency to every project. Choose Standout for a partnership founded on excellence and craftsmanship.

our approach

uncompromising

quality

At Standout, we pride ourselves on providing the highest quality steel components and warranty all our products to support our customer needs

Unparalleled

customer service

Standout provides a differentiated customer experience by providing excellent response times and customer support 24/7

Reliable

on-time delivery

We are dedicated to providing on-time delivery and are flexible with expediting orders or adjusting delivery dates to meet our customers evolving needs

Rapid

prototyping

We offer rapid prototyping and commit to providing FREE prototypes for any new component needs

Engineering

support

Our team of engineers are available to our customers,

helping to provide feedback on material, design and application requirements with the goal of identifying cost savings opportunities for our customers

overview of tools

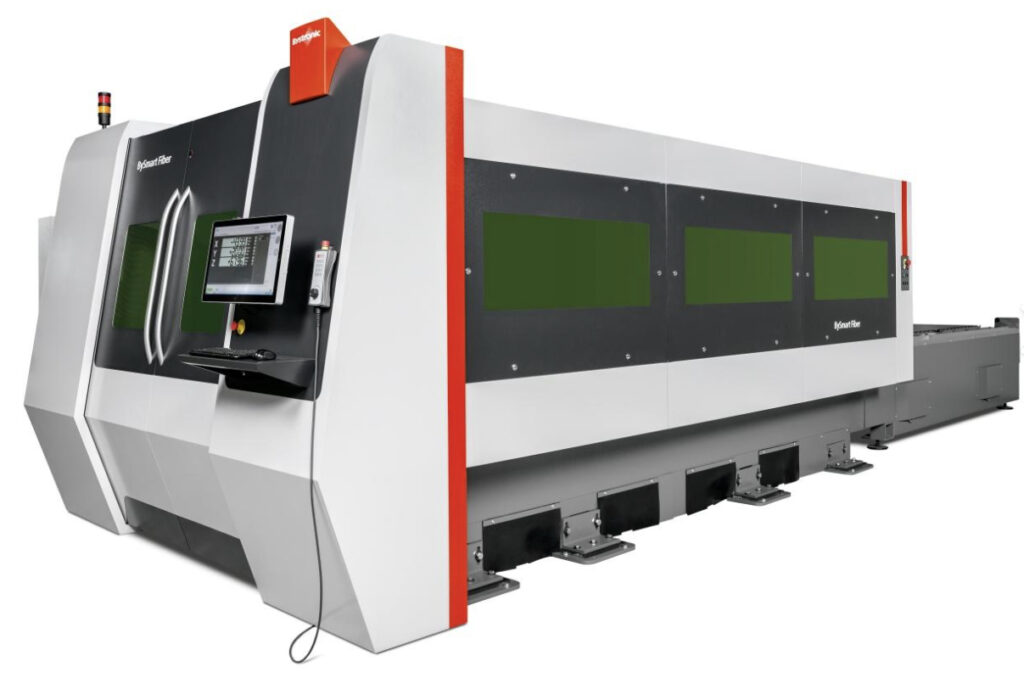

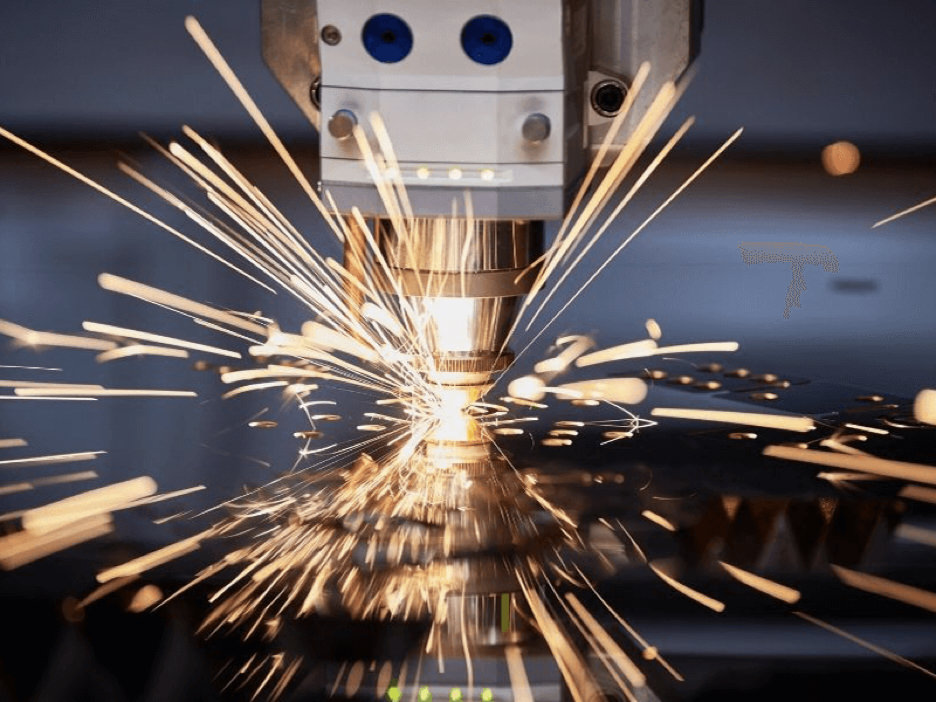

Bystronic 4K Fiber Laser

Elevating Precision Cutting Across Industries

Unleash the potential of the Bystronic 4K Fiber Laser, a game-changer for diverse industries seeking top-notch cutting capabilities. This machine, equipped with a powerful 4KW laser source, stands out in its ability to handle stainless steel, aluminum, and mild steel with unparalleled efficiency and precision. Here’s why it’s your go-to solution:

Benefits:

- Versatility: Seamlessly cut through materials such as stainless steel, aluminum, and mild steel, adapting to the needs of various industries.

- Efficiency: The 4KW laser source ensures swift and precise cutting, boosting overall manufacturing efficiency.

- Application Range: From intricate sheet metal designs to robust industrial components, this machine caters to a broad spectrum of manufacturing needs.

- Flexibility in Thickness: Whether dealing with thin sheets or thicker plates, the Bystronic 4K Fiber Laser provides the flexibility required for diverse projects.

Experience the agility, precision, and versatility your projects demand with the Bystronic 4K Fiber Laser. Elevate your manufacturing capabilities today.

Xpert Pro 150 Press Brake

Precision Bending for Varied Industries

Precision bending is provided with the Xpert Pro 150 Press Brake, a cutting-edge solution designed for diverse industrial applications. This powerful machine redefines the standards of accuracy and efficiency in metal forming. Here’s why it stands out:

Benefits:

- Precision Bending: The Xpert Pro 150 ensures precise bending, meeting the high-quality standards demanded by industries across the board.

- Versatility: Whether you’re in RV, automotive, aerospace, or any industry requiring precise metal forming, this press brake adapts to various bending needs.

- High Tonnage Capacity: With a substantial tonnage capacity, the Xpert Pro 150 effortlessly handles a wide range of materials and thicknesses.

- Quality Output: Achieve consistently high-quality bends, ensuring the precision required for intricate components and structural elements.

Whether you’re crafting complex components or forming structural elements, the Xpert Pro 150 Press Brake empowers your metal forming capabilities. Elevate your bending precision and efficiency with this exceptional machine.

DNM5700 Vertical Machining Center

Elevating Precision Machining Across Industries

The DNM5700 Vertical Machining Center, crafted by Doosan Machine Tools, stands as a pinnacle in precision engineering, catering to the diverse needs of industries such as automotive, aerospace, and mold making. Renowned for its cutting-edge technology and reliability, the DNM5700 epitomizes efficiency and accuracy in machining operations.

Benefits:

- High Precision: The machine is engineered to deliver precise machining results with tight tolerances, making it suitable for applications where accuracy is critical.

- Versatility: The DNM5700 is designed to accommodate a wide range of machining tasks, from roughing to finishing operations, making it adaptable to diverse manufacturing needs.

- Automation Compatibility: The DNM5700 can be integrated with automation systems for unmanned operation, enhancing productivity and reducing labor costs.

- Energy Efficiency: With energy-saving features and eco-friendly design, the machine minimizes energy consumption without compromising on performance, contributing to sustainable manufacturing practices.

Vertical Machining Center represents a state-of-the-art solution for manufacturers seeking reliable, high-performance machining equipment capable of meeting the demands of modern industrial applications.

LYNX 2100 LSYB Turning Center

Precision Turning for Various Industries

Turning is a machining process used to create cylindrical parts by removing material from a workpiece. In this process, a cutting tool is used to remove material from the workpiece while it rotates on a spindle. The cutting tool is typically fed into the rotating workpiece to produce the desired shape, size, and surface finish.

Benefits:

- High Precision Turning: Engineered to deliver exceptional precision in turning operations, the LYNX 2100 LSYB ensures impeccable accuracy and surface finish, catering to industries where precision is paramount.

- Dual Spindle and Y-axis Boring Capability: Equipped with dual spindles and a Y-axis boring feature, the LYNX 2100 LSYB facilitates complex machining tasks, allowing for simultaneous turning and milling operations on a single machine.

- Multi-Tasking Versatility: Designed to handle a diverse range of machining tasks, from simple turning to complex milling and drilling operations, the LYNX 2100 LSYB offers versatility to meet varied manufacturing requirements.

- Integrated Automation Capability: With compatibility for automation systems, the LYNX 2100 LSYB supports unmanned operation, enhancing productivity and reducing labor costs.

With its advanced features, versatile capabilities, and reliable performance, the LYNX 2100 LSYB is poised to revolutionize turning operations, offering manufacturers a powerful solution to meet the evolving challenges of modern industrial production.

Brother SPEEDIO R450Xd1 Machining

Elevating Precision Machining Across Industries

The Brother SPEEDIO R450Xd1 is an advanced machining center renowned for its high-speed performance and exceptional precision. Developed by Brother Industries, a leading manufacturer of machining solutions, the SPEEDIO R450Xd1 combines cutting-edge technology with innovative design to meet the demands of modern manufacturing industries.

Benefits:

- High-Speed Machining: The SPEEDIO R450Xd1 is engineered for high-speed machining operations, allowing for rapid material removal and increased productivity without compromising on accuracy or surface finish.

- Advanced Spindle Technology: Equipped with a powerful spindle, the SPEEDIO R450Xd1 offers high-speed rotational capabilities, enabling efficient machining of a wide range of materials with precision and consistency.

- Multi-Axis Machining: Featuring multi-axis capabilities, including simultaneous 5-axis machining, the SPEEDIO R450Xd1 allows for complex machining tasks, facilitating the production of intricate components with ease.

- Automation Integration: With compatibility for automation systems, the SPEEDIO R450Xd1 supports unmanned operation, enabling continuous machining and minimizing downtime for increased throughput and cost-effectiveness.

With its advanced features, compact design, and high-speed capabilities, the SPEEDIO R450Xd1 offers manufacturers a powerful solution to meet the dynamic demands of today’s manufacturing environment, ensuring optimal performance and efficiency in machining operations.

Industries we serve

RV Products

RV Products Boating

Boating Aerospace

Aerospace General Fabrication

General Fabrication